In the fast-paced world of packaging, selecting the right machinery supplier is crucial for any business aiming to stay competitive and efficient. As global demand for innovative packaging solutions surges, China has emerged as a leading hub for Blow molding machine manufacturing. Among the notable players in this sector, Sentis Equipment Co.,Ltd (abbreviated as Sentis) stands out for its commitment to quality, innovation, and customer satisfaction. This article explores why partnering with blow molding machine China suppliers like Sentis is a strategic move for your packaging needs.

Latest Trends in Blow Molding Technology

The packaging industry is evolving rapidly, with sustainability and automation taking center stage. Blow molding machines, particularly those manufactured in China, are incorporating advanced features such as energy-efficient drives, precise control systems, and compatibility with recycled materials. Sentis has been at the forefront of integrating these technologies, ensuring their machines not only meet but exceed international standards.

China’s competitive edge in blow molding technology is driven by a robust supply chain, extensive R&D, and a focus on cost-effective production. This allows suppliers like Sentis to offer high-quality equipment at attractive prices, making them a preferred choice for businesses worldwide.

What Sets Sentis Apart?

- Comprehensive Product Range: Sentis offers a wide variety of blow molding machines, from extrusion blow molding to injection blow molding, catering to diverse packaging requirements.

- Customization: Sentis understands that every client has unique needs. Their engineering team works closely with customers to deliver tailor-made solutions, whether for small-scale startups or large-scale production lines.

- After-Sales Support: The company’s commitment extends beyond the sale. Sentis provides installation, training, and ongoing technical support, ensuring seamless operation and minimal downtime.

- Global Reach: With an expanding international presence, Sentis has successfully delivered machinery to clients in over 50 countries, reinforcing its reputation as a trusted global supplier.

Industry Insights: Why China Leads in Blow Molding Machines

China’s manufacturing ecosystem is uniquely positioned to support the production of high-quality blow molding machines. The country boasts a skilled workforce, advanced manufacturing infrastructure, and a strong focus on innovation. This has spurred the growth of companies like Sentis, which leverage these advantages to deliver state-of-the-art equipment.

Moreover, the global shift towards eco-friendly packaging has prompted Chinese suppliers to invest heavily in research and development. Sentis, for example, has introduced machines that enable the use of biodegradable and recycled plastics, aligning with the latest environmental regulations and consumer preferences.

Key Advantages of Choosing Blow Molding Machine China Suppliers

| Advantage | Description |

|---|---|

| Cost Efficiency | Lower manufacturing costs in China translate to competitive pricing for buyers worldwide. |

| Technological Innovation | Continuous investment in R&D ensures access to the latest blow molding advancements. |

| Customization | Flexible production capabilities allow for tailored solutions to meet specific client needs. |

| Scalability | Ability to handle both small-batch and large-scale production requirements. |

| Global Logistics | Strong export networks ensure timely delivery and reliable service worldwide. |

Spotlight: Blow Molding Machine and Bottle Making Machine

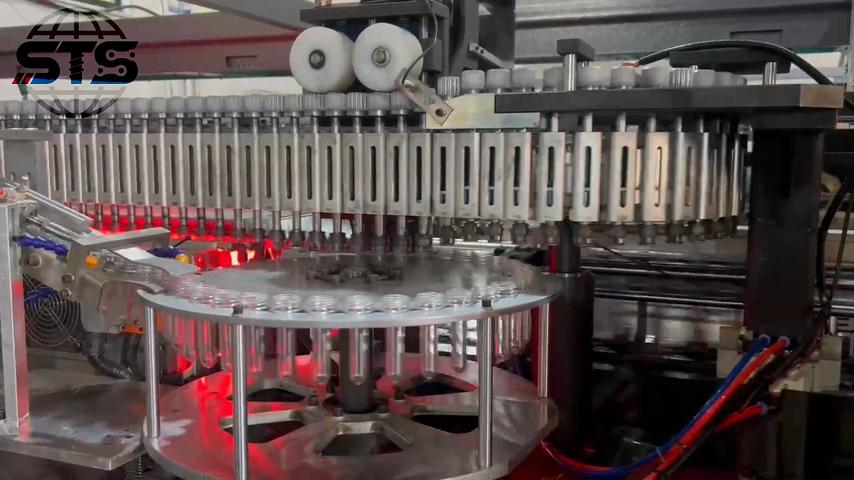

When discussing packaging machinery, two keywords often arise: blow molding machine and bottle making machine. While they are sometimes used interchangeably, they refer to specific processes and equipment. Blow molding machines, such as those produced by Sentis, are designed to form hollow plastic products by inflating heated plastic into a mold cavity. This technology is widely used for manufacturing bottles, containers, and other packaging items.

A bottle making machine is a specialized type of blow molding machine focused on producing plastic bottles of various shapes and sizes. Sentis offers both standalone bottle making machines and integrated systems that streamline the entire production process, from raw material handling to finished product inspection. By investing in advanced blow molding and bottle making machines from China, businesses can achieve higher productivity, consistent quality, and lower operating costs.

Industry Expansion: Applications Beyond Packaging

The versatility of blow molding technology extends far beyond conventional packaging. Industries such as automotive, healthcare, and consumer goods are increasingly adopting blow molding machines for producing components like fuel tanks, medical containers, and household items. Sentis has responded to this trend by diversifying its product portfolio, offering machines capable of handling a wide range of materials and product specifications.

This expansion not only highlights the adaptability of Chinese suppliers but also underscores the importance of choosing a partner with a proven track record in both innovation and reliability.

Conclusion: Partner with Sentis for Future-Ready Packaging Solutions

In an era where efficiency, sustainability, and innovation are paramount, selecting the right blow molding machine China supplier can make all the difference. Sentis Equipment Co.,Ltd combines technical expertise, customer-centric service, and a forward-looking approach to deliver solutions that empower businesses to thrive in a competitive marketplace. Whether you require a high-performance blow molding machine or a specialized bottle making machine, Sentis is equipped to meet your needs with precision and professionalism.

Stay ahead of industry trends and ensure your packaging operations are future-ready by choosing Sentis as your trusted partner in blow molding technology.