In today’s fast-paced manufacturing environment, the demand for high-quality plastic products is ever-increasing. As a leading innovator in the plastics machinery sector, Sentis Equipment Co.,Ltd (Sentis) is at the forefront of delivering cutting-edge upgrades for extrusion blow molding machines. These upgrades not only ensure superior product quality but also enhance operational efficiency, sustainability, and cost-effectiveness. In this article, we explore the latest advancements in extrusion blow molding technology and how Sentis is empowering manufacturers to stay ahead of the curve.

Industry Overview: The Importance of Extrusion Blow Molding Upgrades

The extrusion blow molding process is a cornerstone in the production of hollow plastic parts such as bottles, containers, and automotive components. As global industries place greater emphasis on precision, consistency, and environmental responsibility, the need for advanced blow molding machine upgrades has never been more pressing. Manufacturers are seeking solutions that minimize defects, reduce material waste, and deliver consistent quality across high-volume production runs.

Sentis recognizes these industry trends and has invested heavily in research and development to offer state-of-the-art upgrades that set new benchmarks in extrusion blow molding. These upgrades are designed to address common challenges such as uneven wall thickness, slow cycle times, and excessive energy consumption.

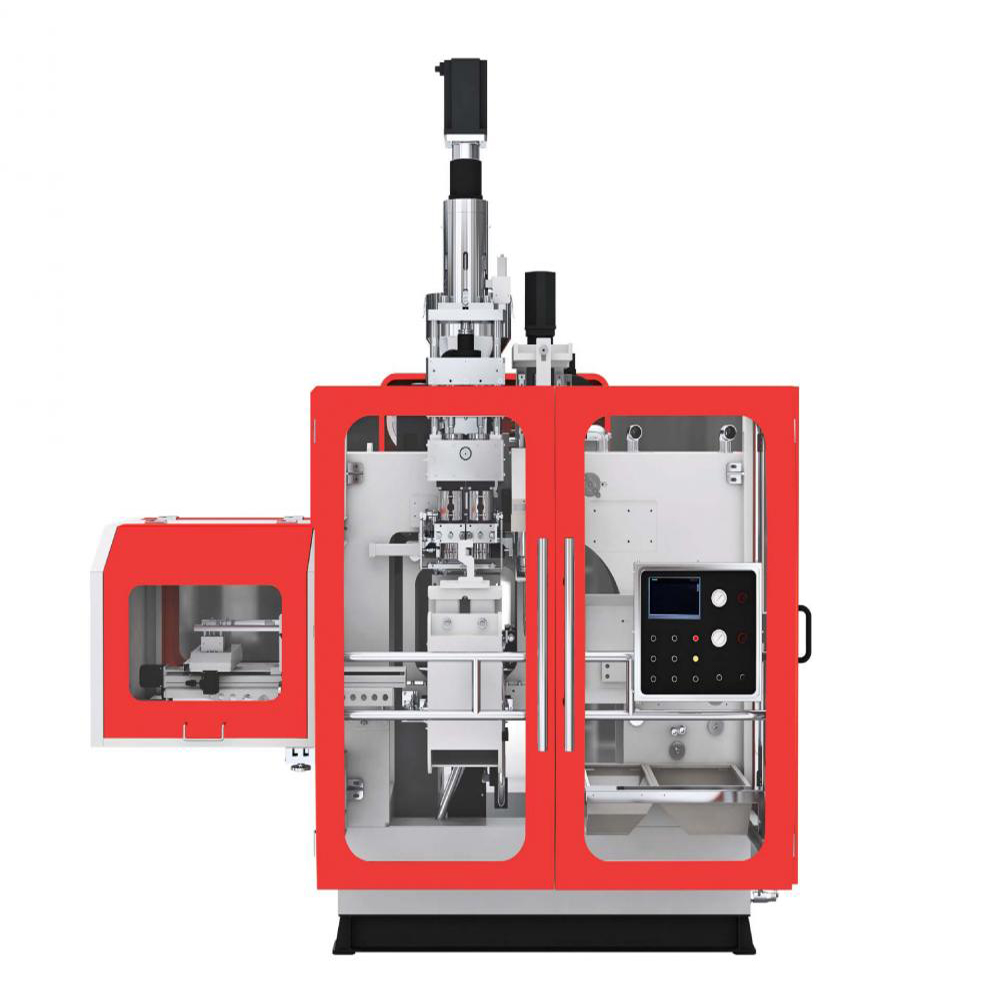

all electric oil bottle blowing machine

Central feeding systems

coconut water bottle blow molding machines

Key Machine Upgrades from Sentis

- Precision Parison Control Systems: Sentis has introduced advanced parison control systems that utilize real-time monitoring and feedback to ensure uniform wall thickness. This upgrade significantly reduces the risk of weak spots and improves the overall structural integrity of molded products.

- Energy-Efficient Heating Technology: Modern extrusion blow molding machines from Sentis are equipped with state-of-the-art heating elements that optimize energy usage. This not only lowers operational costs but also aligns with global sustainability goals.

- Automated Quality Inspection: Sentis integrates intelligent vision systems that perform on-the-fly inspections, detecting defects before products leave the production line. This proactive approach minimizes waste and increases yield.

- Modular Machine Design: The modular design philosophy adopted by Sentis allows for easy upgrades and maintenance, ensuring minimal downtime and maximum flexibility for manufacturers.

These innovations are transforming the way manufacturers approach extrusion blow molding, enabling them to produce superior quality products while maintaining competitive costs.

Industry Trends Shaping the Future of Blow Molding

The plastics industry is undergoing a significant transformation, driven by consumer demand for sustainable packaging and regulatory pressures to reduce environmental impact. As a result, extrusion blow molding machine manufacturers like Sentis are prioritizing eco-friendly upgrades and digitalization.

One notable trend is the shift towards recycled plastic blow molding machines. Sentis has responded by developing machines compatible with high percentages of recycled resins, allowing manufacturers to meet sustainability targets without compromising product quality. These machines are engineered to handle the unique flow characteristics and impurities often present in recycled materials.

Another key development is the integration of blow molding machine automation. Sentis provides automation solutions that streamline the entire production process—from raw material feeding to finished product packaging. Automation not only boosts productivity but also reduces the risk of human error, further enhancing product consistency and quality.

Case Study: Real-World Impact of Sentis Upgrades

A leading beverage packaging company recently partnered with Sentis to upgrade its extrusion blow molding lines. By implementing Sentis’s precision parison control and automated inspection systems, the company achieved a 20% reduction in material usage and a 30% decrease in production defects. Additionally, the integration of recycled plastic blow molding machines enabled the company to launch a new line of eco-friendly bottles, meeting both consumer expectations and regulatory requirements.

Benefits of Upgrading with Sentis

| Upgrade Feature | Benefit |

|---|---|

| Precision Parison Control | Consistent wall thickness, reduced defects |

| Energy-Efficient Heating | Lower energy bills, improved sustainability |

| Automated Quality Inspection | Higher yield, reduced waste |

| Modular Design | Easy maintenance, scalable upgrades |

| Recycled Plastic Compatibility | Supports circular economy initiatives |

| Automation Integration | Increased productivity, reduced labor costs |

These comprehensive upgrades underscore Sentis’s commitment to delivering value-added solutions that address the evolving needs of the plastics industry.

Looking Ahead: The Role of Innovation in Blow Molding

As the global market for plastic packaging and components continues to expand, innovation in extrusion blow molding technology will be essential. Sentis is dedicated to pushing the boundaries of what’s possible, with ongoing investments in digitalization, sustainability, and process optimization. By staying ahead of industry trends and anticipating customer needs, Sentis ensures that its partners are well-equipped to thrive in a competitive landscape.

For manufacturers seeking to elevate their production capabilities, investing in Sentis’s extrusion blow molding machine upgrades is a strategic move. With a proven track record of delivering superior quality, efficiency, and sustainability, Sentis remains the partner of choice for forward-thinking companies worldwide.

Contact Sentis Equipment Co.,Ltd

To learn more about how Sentis can help you achieve superior quality with the latest extrusion blow molding machine upgrades, visit the Sentis website or contact their technical support team today.