Sentis Equipment Co.,Ltd

Products

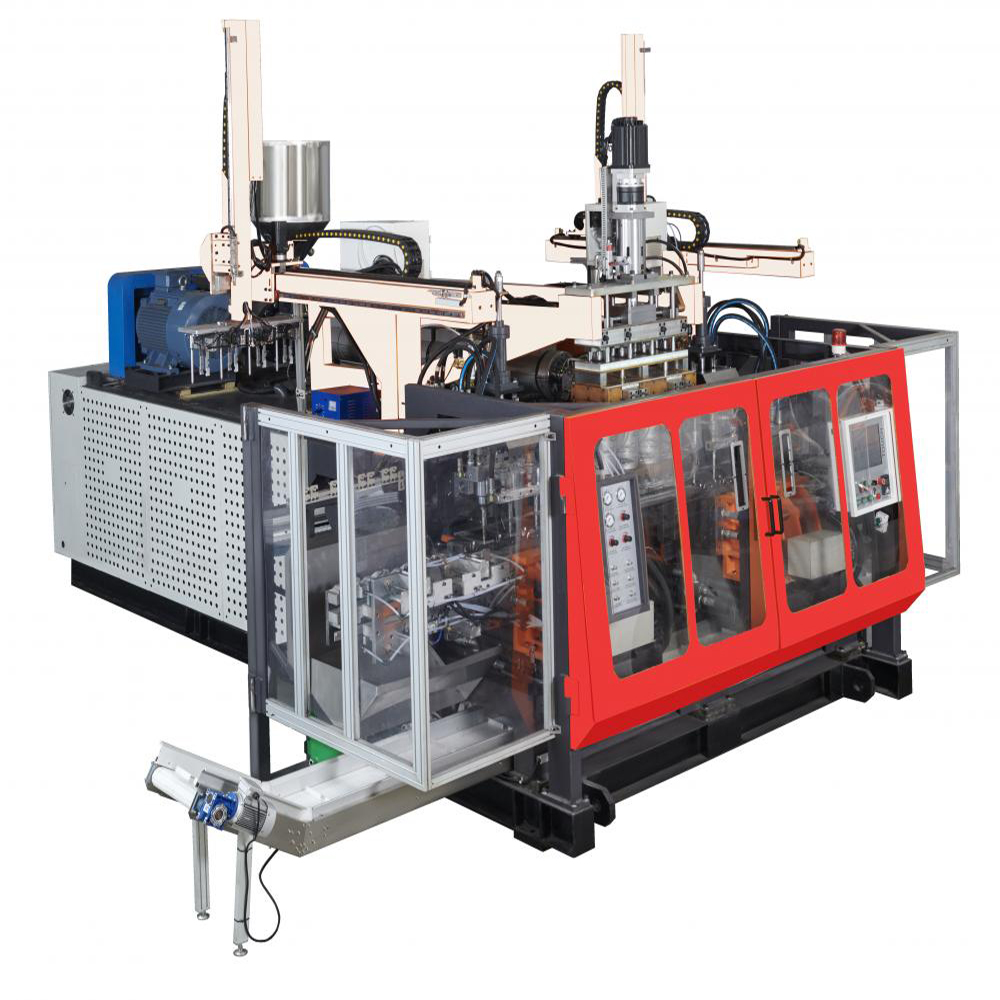

Soy sauce bottle blowing machine

Social Profiles

Description:

Introducing our latest innovation in soy sauce bottle production: the soy sauce bottle blow molding machine. This cutting-edge machine is equipped with advanced features that ensure greater precision, efficiency and safety in the manufacturing process.

One of the main features of our soy sauce bottle blow molding machine is the electronically controlled clamp frame. This innovative design allows for precise control and adjustment, which improves the precision of soy sauce bottle production. The new horizontally movable clamp frame design features balanced force, high speed, low center of gravity and stable operation. In addition, the lower clamp frame improves adjustment efficiency, making the production process more streamlined.

Another important component of our soy sauce bottle blow molding machine is the blow needle. This important part of the machine allows the parison thickness to be adjusted from the outside, ensuring precise and consistent production of soy sauce bottles. This feature not only improves the quality of the bottle, but also effectively improves the safety of the operator, which is an important hazardous environment task in any manufacturing.

Our soy sauce bottle blow molding machine is designed to meet the high demands of the industry and provide a reliable and efficient solution for soy sauce bottle production. With advanced features and cutting-edge technology, this machine is the perfect choice for companies seeking to optimize production processes and improve product quality.

In conclusion, our soy sauce bottle blow molding machine provides unparalleled precision, efficiency and safety in soy sauce bottle production. With its electronic needle control frame and advanced blow molding functions, this machine is a must-have for any business that wants to stay ahead in a highly competitive market. Experience our difference in soy sauce bottle blow molding machine and take your production to the next level.

Features

Clamping frame

Tripod frame adopts electronic ruler control for higher precision

New horizontal motion frame frame design.

Southeast frame has balanced force, fast speed and low center of gravity.

The bottom bandwidth frame ensures higher adjustment efficiency.

Blow needle

External parison thickness adjustment.

Effectively protect the safety of operators.

Safety door

The safety door adopts a free opening structure, prepares ample installation space

Mold, extremely efficient.

Durable aluminum alloy side box.

Technical parameters

| 项目 Item | SL2-L5×2-2A(90-55) | SL2-L5×2-1A(90) | ||

| 类别 Category | / | 海湾Gulf | 单层 Single layer | |

| 最大吹氣量Maximum air volume | 大号 Large | 5 | 5 | |

| 材料Material | / | 聚乙烯、聚丙烯Polyethylene, Polypropylene | 聚乙烯、聚丙烯Polyethylene, Polypropylene | |

| 模头数量 Number of Dies |

/ | 2 | 2 | |

| 模头距离(中心到中心)Die head distance (center to center) | 日 | 250,280 | 250,280 | |

| 净重 Net weight | 公斤KG | 17500 | 17500 | |

| MM, length × width × height | 4982×4078×3398 | 4978×4138×3288 | ||

| 模特Model | ||||

| 模具加热区Mold heating zone | / | 5 | 5 | |

| 模具加热Mold heating | 年Year | 23.85 | 16.61 | |

| 夹紧单元Clamping unit | ||||

| 站位数量Number of stations | / | 2 | 2 | |

| 最小合模距离Minimum mold distance | 日 | 230 | 230 | |

| 最大開模距离Maximum mold opening distance | 日 | 480 | 480 | |

| 模具板的顶部Top of the mold plate | 毫米MM,宽×高width × height | 615×505 | 615×505 | |

| 托拉行程Torah Itinerary | 日 | 650 | 650 | |

| 夹壓力Clamping pressure | 千牛KN | 256 | 256 | |

| 挤出机系统Extruder system | ||||

| 藝術機構Art Institutions | 日 | 90 | 55 | 90 |

| 排除机器长度/直径比Excluding machine length/diameter ratio | 長路比 | 24 | 23 | 24 |

| 阻止机器旋转Stop the machine from rotating | 转/分 | 10-66 | 20-40 | 10-66 |

| 最大挤出能力Maximum extrusion capacity | 公斤/小时KG/H | 160 | 二十五 | 160 |

| 挤出機械Extrusion machinery | 年 | 三十七 | 7.5 | 三十七 |

| 機械加热區Mechanical heating zone | / | 4 | 3 | 4 |

| 料筒加热Barrel heating | 年 | 16 | 6.34 | 16 |

| 放棄 | 年 | 0.72 | 0.08 | 0.72 |

| 电力系统Power System | ||||

| 油劑電腦Oil computer | 年 | 三十 | 三十 | |

| 液压系统额定工作压力 Rated working pressure of hydraulic system | 兆帕Mpa | 0.1 | 0.1 | |

| 气动系统额定工作压力 Rated working pressure of pneumatic system | 兆帕Mpa | 0.8 | 0.8 | |

| 冷却系统额定工作压力 Rated working pressure of cooling system | 兆帕Mpa | 0.4 | 0.4 | |

| 通用产品消耗气量(压缩) General product gas consumption (compression) | 立方米/小时Cubic meter/h | 19 | 19 | |

| 热切刀功率Hot cutter power | 年 | 3 | 3 | |

| 总销量Total sales | 年 | 126.59 | 105.43 | |

| 评论 | ||||

| 总装机功率 Total installed power | 大号 | 46#300 | 46#300 | |

| 冷水机推荐(风冷/水冷) Chiller recommendation (air cooling/water cooling) | 马 | 15/10 | 15/10 | |

| 空压机推荐(加储气罐) Air compressor recommendation (Add a gas storage tank) | 马 | 10 | 10 | |

| 以上所有机器均任选配100点型坯控制系统,其变化如下。 All of the above machines are optionally available with a 100-point parison control system, which varies as follows. | ||||

| 采用型坯控制后After adopting parison control | ||||

| 協助電子計算機 Assisting Computers | 年 | 5.5 | 5.5 | |

| 总销量Total sales | 年 | 110.45 | 110.93 | |