Sentis Equipment Co.,Ltd

Products

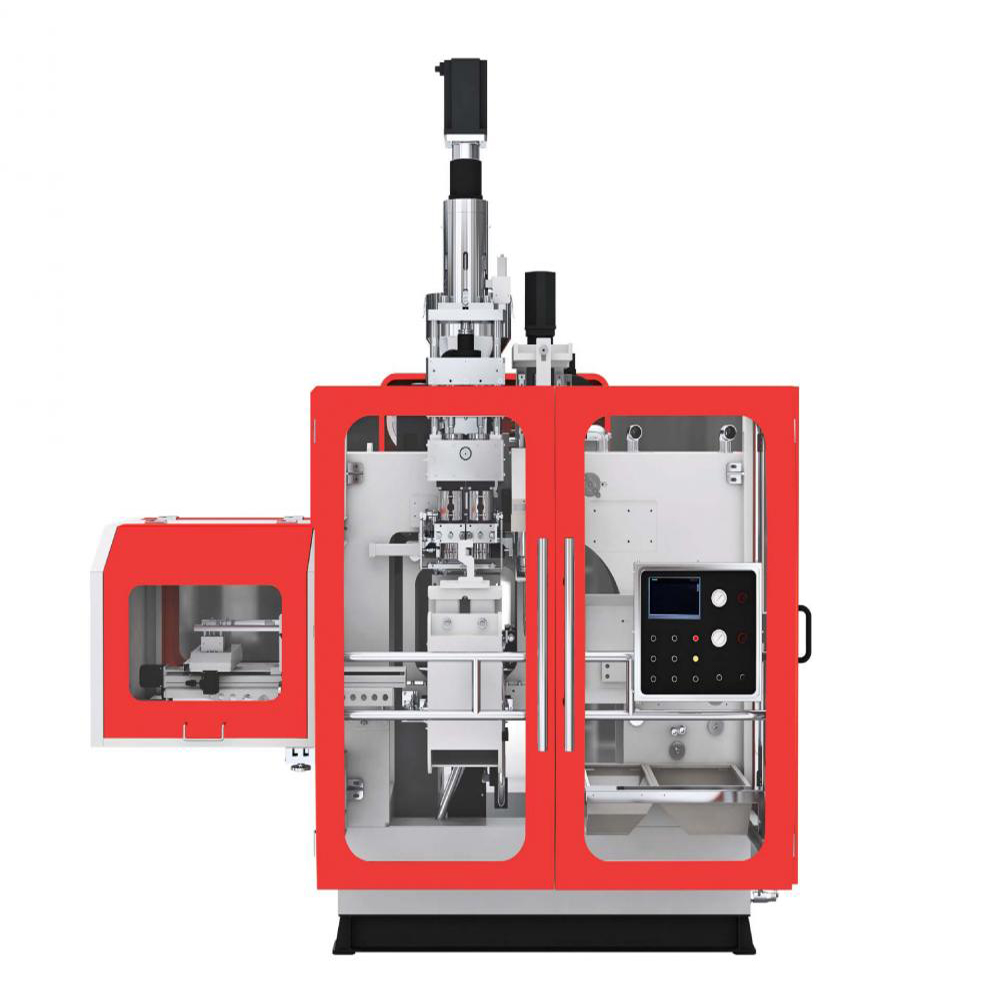

Cosmetic bottle blow molding machine

Introducing ourcosmetic bottle blow molding machine! Featuring the latest technology and innovative design, this machine is ideal for producing high-quality cosmetic bottles efficiently and accurately.

Social Profiles

Description:

Introducing our cosmetic bottle blow molding machine! Featuring the latest technology and innovative design, this machine is ideal for efficiently and accurately producing high-quality cosmetic bottles.

The die extruder is connected to a pressure sensor balanced manifold and features a quick-clean design milling plate, which ensures smooth and even distribution of the molten plastic, producing uniform and flawless bottles. The throttle valve can be adjusted from the front for each layer, each parison, and even for multiple heads, allowing full control of the production process.

We pride ourselves on our advanced melt flow rheology calculations, providing options such as spiral, heart and spider distributors. This ensures optimal flow and distribution of the plastic, producing bottles with consistent weight and thickness.

Our extruders also offer grooved or smooth bushing extruders as options to meet different production needs. Our machines consume up to 0.25kw/kg, which is not only efficient but also environmentally friendly.

With our commitment to innovation and quality, our cosmetic bottle blow molding machines are the perfect solution for cosmetic manufacturers looking to increase their production capabilities. We are dedicated to providing our customers with the best equipment and are confident that our machines will exceed your expectations.

Experience the future of cosmetic bottle production with our advanced blow molding machines. Contact us today to learn more about how our machines can benefit your production process and take your cosmetic bottle production to the next level.

feature

Accurate:

The clamping device/carriage/blow needle movement has a repeatability of up to 0.01 mm.

Quiet

The noise level during operation is less than 70db.

Fully electric clamping system

The swing-type carriage structure moves in an arc.

Clamp plate and bracket base made of aviation aluminum alloy.

The action is fast, accurate and stable, suitable for light weight and high strength

Classic ARC movement, stable and fast

Single station: suitable for small orders, saving costs

Moulds and auxiliary machines are easy to change.

Patented clamping technology saves 50%-60% energy compared to hydraulic presses

Technical Parameters

| category | / | Single station, double head, 2 layers | ||

| Maximum air volume | large | 0.5L | ||

| Material | / | Polyethylene terephthalate | ||

| Number of Dies | / | 2 | ||

| Die head distance (center to center) | Millimeters | 125 | ||

| net weight | Kilogram | 6000 | ||

| Machine size | mm, length x width x height | Length 3295×Width 1936×Height 3347 | ||

| Die head | ||||

| Die head heating zone | / | 16 | ||

| Die head heating power | kilowatt | 10.58 | ||

| Number of stations | / | 1 | ||

| Minimum mold distance | Millimeters | 180 | ||

| Maximum mold opening distance | Millimeters | 330 | ||

| Mold plate size | mm, width x height | 300× 280 | ||

| Bracket travel | Millimeters | 300 | ||

| Clamping force | Thousand Bulls | XXVII | ||

| Extruder system | ||||

| Extruder diameter | Millimeters | 40 | thirty | |

| Extruder length/diameter ratio | Aspect Ratio | XXV | XXV | |

| Extruder speed | RPM | 60-150 | 60-150 | |

| Maximum extrusion capacity | kg/hour | 40 | 15 | |

| Extruder motor rated power | kilowatt | 11 | 5.5 | |

| Barrel heating zone | / | 3 | 2 | |

| Heating power | kilowatt | 6.6 | 3 | |

| Cooling fan power | Aspect Ratio | 0.18 | 0.15 | |

| Power System | ||||

| Blow needle motor power | kilowatt | 3 | ||

| Rated power of clamping motor | kilowatt | 1 | ||

| Rated power of carriage motor | kilowatt | 1.5 | ||

| Left electric control cabinet air conditioner | kilowatt | 0.2 | ||

| Right electric cabinet air conditioner | kilowatt | 0.3 | ||

| Rated working pressure of pneumatic system | MPa | 0.6-0.8 | ||

| Rated working pressure of cooling system | MPa | 0.4 | ||

| General product air consumption (compression) | Cubic meter / hour | 16 | ||

| Hot Knife Transformer Power Supply | kilowatt | 1 | ||

| Total installed power 1 | kilowatt | Chapter 44 | ||

| Note 1 | ||||

| All the above models can be equipped with 100-point wall thickness control system. | ||||

| Servo parison control | ||||

| Wall thickness servo motor rated power | kilowatt | 1 | ||

| Total installed power 2 | kilowatt | Chapter 45 | ||

| Robot | ||||

| Spindle motor rated power | kilowatt | 0.4 | ||

| Auxiliary machine | ||||

| Rotary trimmer | kilowatt | 0.75 | ||

| Finished product power | kilowatt | 0.25 | ||

| Bottle cap conveyor | kilowatt | 0.25 | ||

| Total installed power | kilowatt | Chapter 47 | ||

| notes | ||||

| 1. The heating power of each model is related to the die configuration. Due to different die configurations, the heating power may be slightly different.

2.2. The parameter table is for reference only. The actual model parameters may be adjusted. |

||||