Energy efficiency is rapidly transforming coconut water bottle blow molding machines into smarter, more sustainable, and cost-effective assets for beverage manufacturers. Sentis Equipment Co.,Ltd (Sentis) leads this change with a comprehensive lineup of energy-saving coconut water bottle blow molding equipment, integrating advanced servo drive systems, heat recovery modules, intelligent controllers, and automation. These innovations result in faster production cycles, reduced operating costs, improved bottle quality, and lower environmental impact.

By choosing energy-efficient blow molding machinery from Sentis, producers gain several competitive advantages: reduced power bills, compliance with sustainability regulations, enhanced product consistency, and the ability to market eco-friendly packaging. Sentis’ modular and customizable solutions ensure that every plant’s needs are met, whether upgrading legacy equipment or investing in a new production line. Their commitment to ongoing innovation—such as IoT monitoring, predictive analytics, and renewable energy integration—positions beverage companies for future growth and resilience.

In summary, energy efficiency is not just an operational benefit—it is a strategic asset for coconut water bottle manufacturers. Sentis Equipment Co.,Ltd delivers proven, scalable solutions that maximize output and minimize energy use, helping clients achieve their production, sustainability, and profitability goals.

Can Energy Efficiency Boost Your Coconut Water Bottle Blow Molding Machines?

In the competitive beverage packaging industry, coconut water bottle blow molding machines have become increasingly important. For manufacturers seeking to lower costs, improve sustainability, and boost productivity, energy efficiency is a vital factor. Sentis Equipment Co.,Ltd (abbreviated as Sentis) is at the forefront of integrating energy-efficient technologies in blow molding solutions. This article explores how energy efficiency can enhance your coconut water bottle blow molding machines and the strategic value this brings to your operations.

Understanding Coconut Water Bottle Blow Molding Machines

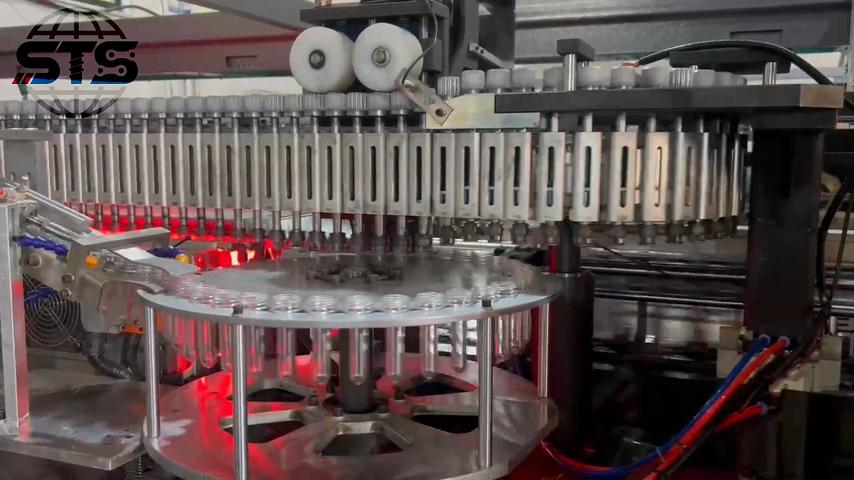

Coconut water bottle blow molding machines are specialized automation equipment used to manufacture lightweight, robust, and hygienic packaging for coconut water. The process involves heating PET or other plastics, then blowing it into a mold to create bottles of desired shape and size. Sentis offers a wide range of blow molding technologies, including:

all electric shuttle blow molding machine

pet carbonated beverage bottle blow molding machine

all electric oil bottle blowing machine

pet beverage bottle blow molding machine

- Automatic coconut water bottle blow molding machine

- Energy-saving coconut water bottle blow molding equipment

- High-speed coconut water bottle blow molding machine

- Low energy consumption coconut water bottle blow molding system

- Servo drive coconut water bottle blow molding machine

- Eco-friendly coconut water PET bottle blow molding machine

- Advanced coconut water bottle manufacturing machinery

- Efficient coconut water bottle blow molding line

- Modular coconut water bottle production blow molding machine

- Intelligent coconut water bottle blow molding controller

Why Energy Efficiency Matters in Blow Molding

Energy efficiency is not just a buzzword—it is a core driver for reducing operational expenses, minimizing environmental impact, and improving overall competitiveness. In coconut water bottle blow molding machines, electricity and heat are two major energy inputs. Reducing energy consumption directly leads to lower utility bills, less carbon footprint, and improved regulatory compliance for beverage producers.

undefined

The Role of Sentis in Energy-Efficient Blow Molding Technology

Sentis has pioneered the use of cutting-edge components and controls to maximize energy savings. Their coconut water bottle blow molding machines feature:

- Servo motor systems for precise control and minimal power loss

- Automatic shut-off and standby modes to eliminate idle energy draw

- Optimized heating elements for fast, uniform plasticization with less energy

- Variable speed blowers and compressors for tailored airflow management

- Energy recovery systems that capture and reuse heat from the process

- Intelligent control panels that monitor energy use in real-time

By integrating these technologies, Sentis ensures that every coconut water bottle blow molding machine delivers optimal output while keeping energy costs in check.

Key Benefits of Energy-Efficient Coconut Water Bottle Blow Molding Machines

- Reduced Operating Costs – Lower electricity and gas bills due to decreased energy consumption.

- Higher Productivity – Fast cycle times and reliable performance thanks to smarter process controls.

- Improved Product Quality – Consistent bottle wall thickness, weight, and strength due to uniform heating and blowing.

- Environmental Sustainability – Less greenhouse gas emissions and resource usage per bottle produced.

- Enhanced Equipment Longevity – Lower wear and tear from optimized motors and drives.

- Regulatory Compliance – Meets global standards for energy efficiency and carbon reduction.

- Competitive Advantage – Ability to market eco-friendly packaging and pass cost savings to customers.

Case Study: Sentis Energy-Saving Coconut Water Bottle Blow Molding Solutions

Sentis recently implemented a high-speed, energy-efficient coconut water bottle blow molding line for a major beverage company in Southeast Asia. The line features modular coconut water bottle production blow molding machines with servo drive technology. The system reduced energy consumption by 35% compared to traditional machines. Heat recovery modules pre-warm preforms using waste heat, and intelligent controllers adjust power settings in real-time based on production demand. Not only did the client reduce their utility costs, but they also achieved higher throughput and improved bottle quality.

How to Choose the Right Energy-Efficient Blow Molding Machine for Coconut Water Bottles

When selecting coconut water bottle blow molding equipment, consider these essential factors:

- Capacity requirements (number of bottles per hour)

- Bottle sizes and shapes

- Energy efficiency ratings and certifications

- Automation level and ease of operation

- Availability of energy recovery and monitoring features

- After-sales support and technical expertise from the supplier

Sentis offers consultation and customization to match the ideal coconut water bottle blow molding machine to your plant’s needs, maximizing both output and savings.

Trends and Innovations in Energy-Efficient Blow Molding

The future of coconut water bottle blow molding machines will be shaped by digitalization, AI-driven process optimization, and advanced energy management. Sentis is investing in:

- IoT-enabled coconut water bottle blow molding controllers

- Predictive maintenance analytics to prevent energy waste from malfunctioning parts

- Remote monitoring for real-time energy performance tracking

- Flexible, modular upgrades to adapt to changing bottle designs and market demands

Integration with Renewable Energy Sources

Forward-thinking beverage producers are coupling energy-efficient coconut water bottle blow molding machines with solar or wind power sources. Sentis systems can be configured for seamless integration with renewable energy inputs, further reducing carbon emissions and enabling sustainable bottle production.

Energy Efficiency: The Sentis Value Proposition

Sentis Equipment Co.,Ltd stands out by delivering coconut water bottle blow molding machines that combine reliability, advanced automation, and industry-leading energy efficiency. Here is a summary table of Sentis’ energy-saving features and their impact:

| Feature | Benefit |

|---|---|

| Servo Drive System | Precise movement, minimal energy loss |

| Heat Recovery Module | Reuses process heat, reduces total energy |

| Intelligent Controller | Real-time energy optimization |

| Automatic Standby Mode | Zero energy use during idle |

| Eco-Friendly Material Handling | Lower emissions, improved sustainability |

Tips for Maximizing Energy Efficiency in Coconut Water Bottle Blow Molding

- Regularly maintain and calibrate heating and blowing components

- Upgrade existing machines with Sentis energy-saving modules

- Train operators in best practices for energy management

- Monitor real-time energy use via smart controllers

- Plan production schedules to match peak energy availability

Conclusion: Energy Efficiency as a Strategic Asset

Adopting energy-efficient coconut water bottle blow molding machines is more than a cost-cutting measure—it is a strategic decision that impacts product quality, brand reputation, and long-term sustainability. Sentis Equipment Co.,Ltd leads the way with advanced technologies that maximize production while minimizing energy use. Whether you are upgrading existing lines or designing new facilities, Sentis’ expertise ensures your coconut water bottle manufacturing remains competitive, sustainable, and future-ready.

Frequently Asked Questions

- Can energy-efficient coconut water bottle blow molding machines reduce long-term costs?

Absolutely. Sentis’ solutions cut energy bills and maintenance costs, resulting in substantial savings over the machine’s lifespan. - How does energy efficiency impact bottle quality?

Uniform heating and controlled blowing from energy-efficient machines produce bottles with consistent wall thickness and strength. - Are Sentis coconut water bottle blow molding machines compatible with different plastics?

Yes. Sentis machines can process PET, PP, and other food-grade plastics. - Does Sentis provide customization for unique bottle shapes?

Sentis offers modular and customizable blow molding machines for a wide range of coconut water bottle designs. - What support does Sentis offer for energy management?

Sentis provides training, technical support, and digital monitoring tools for ongoing energy optimization.

Contact Sentis Equipment Co.,Ltd

For more information about energy-efficient coconut water bottle blow molding machines and tailored solutions, visit Sentis Equipment Co.,Ltd’s website or contact their expert team. Discover how energy efficiency can transform your coconut water bottle production today.