Industry News: The Evolving Landscape of Water Tank Blow Molding Machines

In recent years, the demand for high-quality, durable, and cost-effective water storage solutions has surged across multiple industries. As a result, the spotlight is now on water tank blow molding machine manufacturers to deliver advanced solutions that meet evolving market needs. Sentis Equipment Co.,Ltd (abbreviated as Sentis), a leader in the sector, is at the forefront of this transformation, leveraging innovation to redefine the standards of water tank production.

Understanding Water Tank Blow Molding Machines

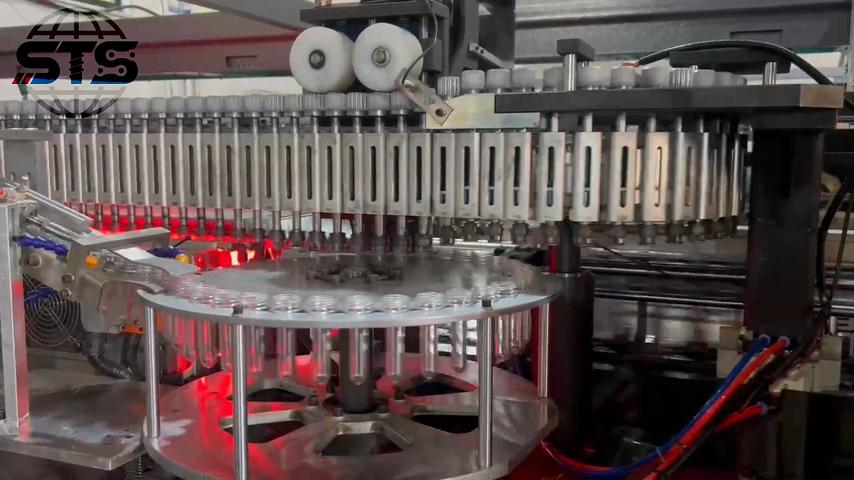

Water tank blow molding machines are specialized equipment designed to manufacture hollow plastic tanks through a process that involves melting plastic and inflating it into a mold cavity. This technology is crucial for producing tanks of varied sizes and shapes, catering to applications in agriculture, residential, industrial, and commercial sectors.

The two critical keywords in this context are blow molding machine and water tank machine. The former refers to the overall technology that shapes plastic products, while the latter focuses on machines specifically engineered for water tank production. Both are central to the ongoing innovation and advancements within the industry.

Sentis: Pioneering Innovation in Blow Molding Technology

Sentis has consistently invested in R&D to introduce next-generation water tank blow molding machines. Their dedication to innovation is evident in the integration of smart automation, energy-efficient systems, and enhanced safety features. By understanding the unique challenges faced by manufacturers, Sentis has tailored its solutions to maximize productivity and minimize operational costs.

all electric shuttle blow molding machine

coconut water bottle blow molding machines

cosmetic bottle blow molding machine

- Smart Automation: Sentis machines utilize advanced PLC controls and IoT connectivity, enabling real-time monitoring and remote diagnostics.

- Energy Efficiency: With variable frequency drives and optimized heating systems, Sentis machines reduce power consumption by up to 30% compared to conventional models.

- Safety & Reliability: Enhanced safety interlocks and robust mechanical design ensure operator protection and machine longevity.

How Innovation Drives Machine Advancements

The rapid pace of technological advancements has propelled the water tank machine market into a new era. Innovations in materials science, digitalization, and process engineering are transforming how water tanks are manufactured. Sentis is at the helm, implementing these breakthroughs to deliver tangible benefits to its clients.

For instance, the adoption of high-performance polymers and multi-layer extrusion technology in Sentis blow molding machines allows for the production of lighter, stronger, and more durable water tanks. This not only extends product lifespan but also reduces transportation and installation costs for end-users.

Digitalization and Data-Driven Manufacturing

Digital transformation is a key driver of innovation in the blow molding machine industry. Sentis has introduced smart sensors and data analytics into its machines, empowering operators to optimize cycle times, detect anomalies, and schedule predictive maintenance. This proactive approach minimizes downtime and enhances overall equipment effectiveness (OEE).

Industry Trends: Sustainability and Customization

Beyond technological advancements, the industry is witnessing a growing emphasis on sustainability and customization. Environmental regulations are pushing manufacturers to adopt eco-friendly practices, and Sentis is leading the way with machines that support recycled materials and reduce carbon footprint.

- Recycled Plastics: Sentis water tank blow molding machines are compatible with a wide range of recycled resins, promoting a circular economy.

- Waste Reduction: Precision molding and material optimization significantly cut down on scrap rates.

- Customization: Sentis offers modular machine designs, enabling clients to produce tanks with unique shapes, colors, and features to suit diverse market needs.

The Role of Training and After-Sales Support

Innovation is not limited to equipment alone. Sentis recognizes the importance of comprehensive training and after-sales support in maximizing the value of its blow molding machines. Through hands-on workshops, digital manuals, and 24/7 technical assistance, Sentis ensures that clients can fully leverage the latest features and maintain peak operational efficiency.

Looking Ahead: The Future of Water Tank Blow Molding Machines

As the global demand for water storage solutions continues to rise, the water tank blow molding machine industry is poised for further growth and transformation. Sentis is committed to staying ahead of the curve by continuously pushing the boundaries of innovation. Future developments are expected to focus on even greater automation, artificial intelligence integration, and further reductions in energy consumption.

In summary, the synergy between innovation and market demand is shaping a new chapter for water tank machine technology. Sentis Equipment Co.,Ltd stands as a testament to the power of forward-thinking R&D, sustainable practices, and customer-centric solutions. By embracing innovation at every stage, Sentis is not only advancing the capabilities of blow molding machines but also empowering manufacturers to deliver superior water tanks to the world.

For more updates on blow molding machine advancements and water tank machine industry trends, stay tuned to Sentis’s latest news page.