Introduction: Ensuring Smooth Production with Sentis

In today’s competitive plastics industry, maintaining the optimal performance of your PE bottle blow molding machine is crucial for efficiency, product quality, and profitability. At Sentis Equipment Co.,Ltd (Sentis), we understand the challenges manufacturers face when troubleshooting issues on the production floor. This guide provides a comprehensive approach to identifying, diagnosing, and resolving common problems associated with PE bottle blow molding machines, while also highlighting industry advancements and the importance of reliable China blow molding machine suppliers.

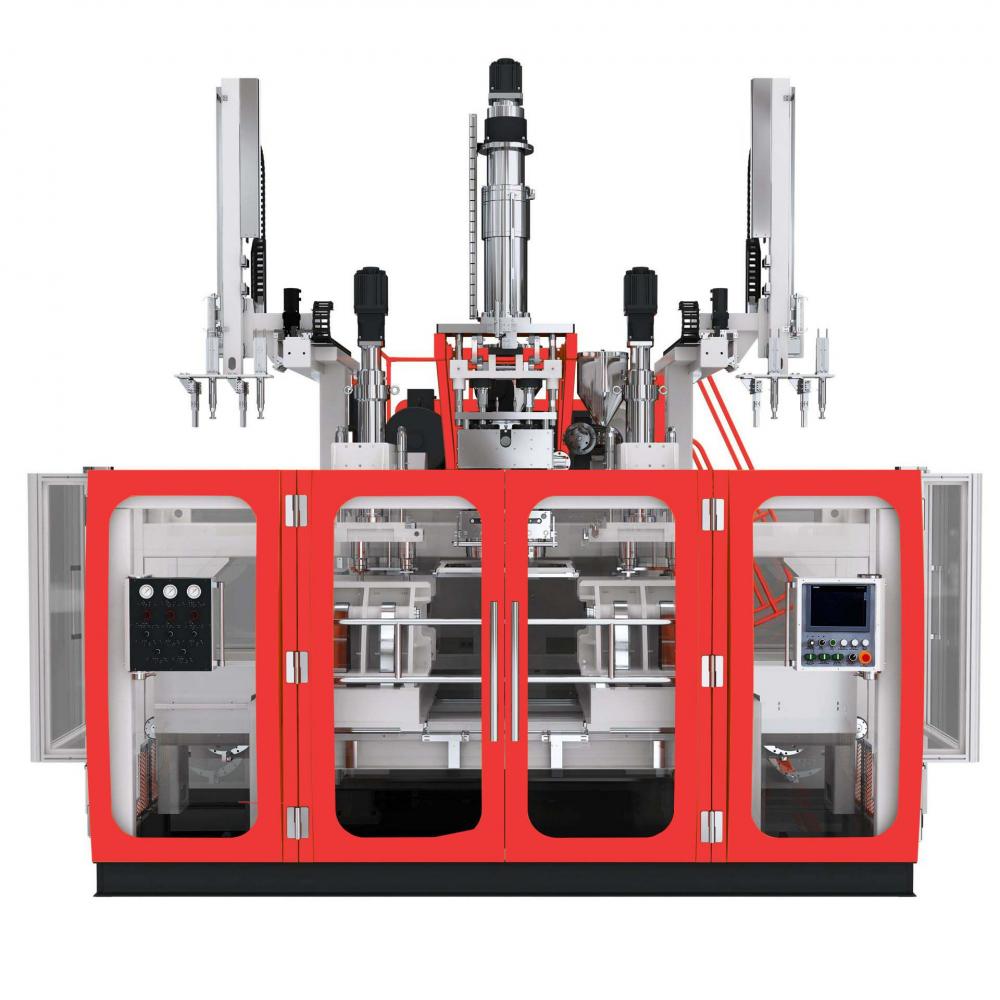

Understanding PE Bottle Blow Molding Machines

PE (Polyethylene) bottle blow molding machines are widely used in the packaging industry for producing bottles, containers, and jars for various applications. These machines utilize blow molding technology to shape heated plastic into hollow forms. As the demand for lightweight, durable, and cost-effective packaging continues to rise, manufacturers are increasingly relying on advanced blow molding equipment to meet stringent quality standards.

Key Components of Blow Molding Machines

- Extruder: Melts and pushes the plastic material forward.

- Mold: Shapes the parison into the desired bottle form.

- Clamping Unit: Holds the mold halves together during blowing.

- Control System: Manages temperature, pressure, and cycle times.

Common Troubleshooting Issues and Solutions

Even with state-of-the-art equipment from trusted China blow molding machine suppliers, issues can arise that affect production efficiency and product quality. Below, Sentis outlines the most frequent challenges and practical solutions:

1. Inconsistent Bottle Wall Thickness

- Cause: Uneven parison extrusion, improper mold temperature, or misaligned die head.

- Solution: Check and calibrate the die head alignment, ensure uniform heating, and adjust extrusion speed as needed.

2. Poor Bottle Clarity or Surface Finish

- Cause: Contaminated resin, incorrect temperature settings, or dirty molds.

- Solution: Use high-quality resin, regularly clean molds, and verify temperature profiles for both extruder and mold.

3. Bottle Leakage or Weak Seams

- Cause: Low blow pressure, improper mold closure, or worn sealing surfaces.

- Solution: Inspect and maintain mold seals, increase blow pressure if necessary, and ensure molds close tightly.

4. Machine Downtime and Cycle Delays

- Cause: Mechanical wear, sensor failure, or software glitches.

- Solution: Schedule preventive maintenance, replace faulty sensors, and update control software as recommended by Sentis.

Industry Trends: Automation and Smart Manufacturing

The global shift towards Industry 4.0 is transforming the blow molding sector. Manufacturers are increasingly adopting automation, IoT-enabled monitoring, and advanced data analytics to enhance machine uptime and product consistency. Sentis is at the forefront of integrating smart controls and remote diagnostics into our blow molding machines, enabling rapid troubleshooting and minimizing unplanned downtime.

Benefits of Partnering with Reliable China Blow Molding Machine Suppliers

Choosing the right supplier is critical. Leading China blow molding machine suppliers like Sentis offer:

- Cutting-edge technology and robust machine designs

- Comprehensive after-sales support and spare parts availability

- Customizable solutions for diverse bottle types and production scales

Preventive Maintenance: The Sentis Approach

Preventive maintenance is vital for maximizing equipment lifespan and minimizing costly breakdowns. Sentis recommends the following best practices:

- Regularly inspect and lubricate moving parts

- Monitor temperature and pressure sensors for accuracy

- Clean molds and extruder components to prevent contamination

- Train operators on proper machine handling and emergency procedures

PE Bottle Manufacturing: Quality Control Essentials

Quality assurance is a cornerstone of successful PE bottle manufacturing. Sentis employs rigorous testing protocols, including wall thickness measurement, drop tests, and leak detection, to ensure every bottle meets industry standards. Additionally, the use of high-quality plastic bottle blow molding machines ensures consistent results and reduces waste.

Case Study: Sentis Troubleshooting Success Story

A leading beverage company recently faced frequent downtime due to inconsistent bottle formation. After consulting with Sentis, a thorough audit revealed a misaligned die head and outdated control software. By realigning the die head and upgrading the control system, the company saw a 25% increase in production efficiency and a significant reduction in scrap rates.

Conclusion: Trust Sentis for Reliable Solutions

Troubleshooting PE bottle blow molding machines requires a systematic approach, technical expertise, and reliable equipment. As a pioneer among China blow molding machine suppliers, Sentis is committed to delivering innovative solutions, comprehensive training, and ongoing support to help manufacturers overcome challenges and stay ahead of industry trends. For more information on our plastic bottle blow molding machines and support services, contact Sentis today.

Related Keywords:

- China blow molding machine suppliers

- Plastic bottle blow molding machine

Stay tuned to Sentis news for the latest updates on blow molding technology, industry best practices, and troubleshooting guides tailored for modern manufacturers.

Tags:PE Blow molding machine application,PE Blow molding machine price