In today’s fast-paced packaging industry, efficiency, reliability, and customization are key factors driving success. As businesses strive to meet growing consumer demands and regulatory standards, selecting the right equipment supplier becomes paramount. Sentis Equipment Co.,Ltd (abbreviated as Sentis) stands out as a leading Blow molding machine supplier, offering advanced solutions tailored to the dynamic needs of modern packaging. This article explores the compelling reasons to partner with a reputable blow molding machine supplier like Sentis, and how this decision can transform your packaging operations.

Latest Industry Trends: Why Packaging Efficiency Matters

Efficiency in packaging is no longer just a competitive advantage—it’s a necessity. With the rise of e-commerce, sustainability concerns, and evolving consumer preferences, manufacturers are under pressure to deliver high-quality, cost-effective, and eco-friendly packaging at scale. Blow molding technology, known for its versatility and automation, has become a cornerstone in producing containers for food, beverages, cosmetics, pharmaceuticals, and household products.

According to recent industry reports, the global blow molding machine market is expected to grow steadily, driven by innovations in automation, material compatibility, and energy efficiency. Companies investing in state-of-the-art blow molding equipment are better positioned to respond to market shifts, reduce waste, and ensure product consistency.

The Sentis Advantage: What Sets Sentis Apart?

As a trusted blow molding machine supplier, Sentis combines technical expertise with a customer-centric approach. Here’s why Sentis is the preferred partner for efficient packaging:

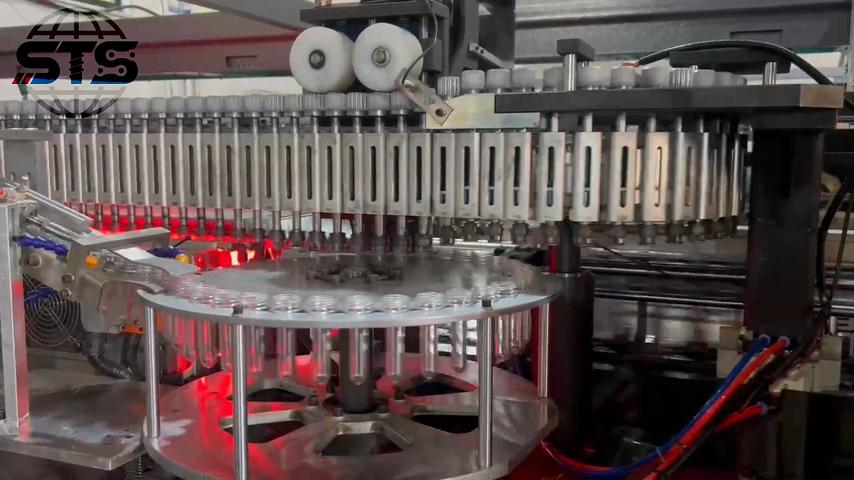

- Advanced Technology: Sentis integrates the latest automation and control systems, ensuring precise molding, reduced cycle times, and minimal material wastage.

- Customization: Every client has unique packaging requirements. Sentis offers tailored solutions, from machine configuration to mold design, supporting diverse applications and container shapes.

- After-Sales Support: Sentis provides comprehensive technical support, spare parts, and training, ensuring smooth operations and rapid troubleshooting.

- Energy Efficiency: With rising energy costs, Sentis machines are engineered for low power consumption, helping clients achieve sustainability targets and cost savings.

- Global Reach: Sentis serves clients worldwide, with a proven track record in various industries and compliance with international standards.

Key Considerations When Choosing a Blow Molding Machine Supplier

The choice of a blow molding machine supplier directly impacts your production efficiency and product quality. Here are some critical factors to keep in mind:

- Machine Versatility: Can the supplier provide machines suitable for different materials (HDPE, PET, PP, etc.) and container sizes?

- Technical Expertise: Does the supplier offer guidance on machine selection, installation, and process optimization?

- Quality Assurance: Are the machines built to meet rigorous quality standards and certifications?

- Service Network: Is there prompt access to maintenance, spare parts, and remote troubleshooting?

Sentis excels in all these areas, making it a reliable partner for businesses aiming to scale and innovate their packaging lines.

Industry Insights: The Role of Blow Molding in Sustainable Packaging

With growing emphasis on environmental responsibility, companies are seeking packaging solutions that minimize ecological impact. Blow molding technology, especially when paired with recyclable materials, offers significant advantages. Sentis has invested heavily in developing machines that support the use of bio-based plastics and recycled resins, enabling clients to reduce their carbon footprint without compromising on performance.

Moreover, the automation capabilities of modern blow molding machines help in optimizing material usage and reducing production scrap. This not only contributes to sustainability goals but also enhances profitability by lowering operational costs. As regulations tighten around single-use plastics and waste management, partnering with an innovative supplier like Sentis ensures your business stays ahead of the curve.

Blow molding machine price and Pet Bottle Blow Molding Machine

When evaluating equipment investments, two common concerns are blow molding machine price and the suitability of a pet bottle blow molding machine for specific applications. Sentis offers competitive pricing models, balancing upfront investment with long-term operational savings. The company’s range of PET bottle blow molding machines is designed for high-speed, precision manufacturing, making them ideal for beverage and personal care industries. Sentis experts work closely with clients to recommend the most cost-effective and high-performance solutions, ensuring maximum ROI.

Conclusion: Make the Smart Choice with Sentis

In the rapidly evolving packaging landscape, efficiency, quality, and adaptability are essential for success. By choosing Sentis as your blow molding machine supplier, you gain access to cutting-edge technology, tailored solutions, and a partnership focused on your long-term growth. Whether you are upgrading your existing lines or expanding into new markets, Sentis delivers the expertise and support needed to achieve efficient, sustainable, and profitable packaging operations.

Stay ahead of industry trends—choose Sentis for your next blow molding machine investment and experience the difference a dedicated supplier can make.