In today’s competitive packaging industry, efficiency and high output are the cornerstones of success. Sentis Equipment Co.,Ltd (abbreviated as Sentis) stands at the forefront of innovation, offering advanced bottle blow molding machines that cater to the ever-increasing demands of manufacturers worldwide. This latest news article explores how Sentis is redefining high-output production, the technology behind their solutions, and the impact on the global packaging sector.

Meeting the Demand for High Output Production

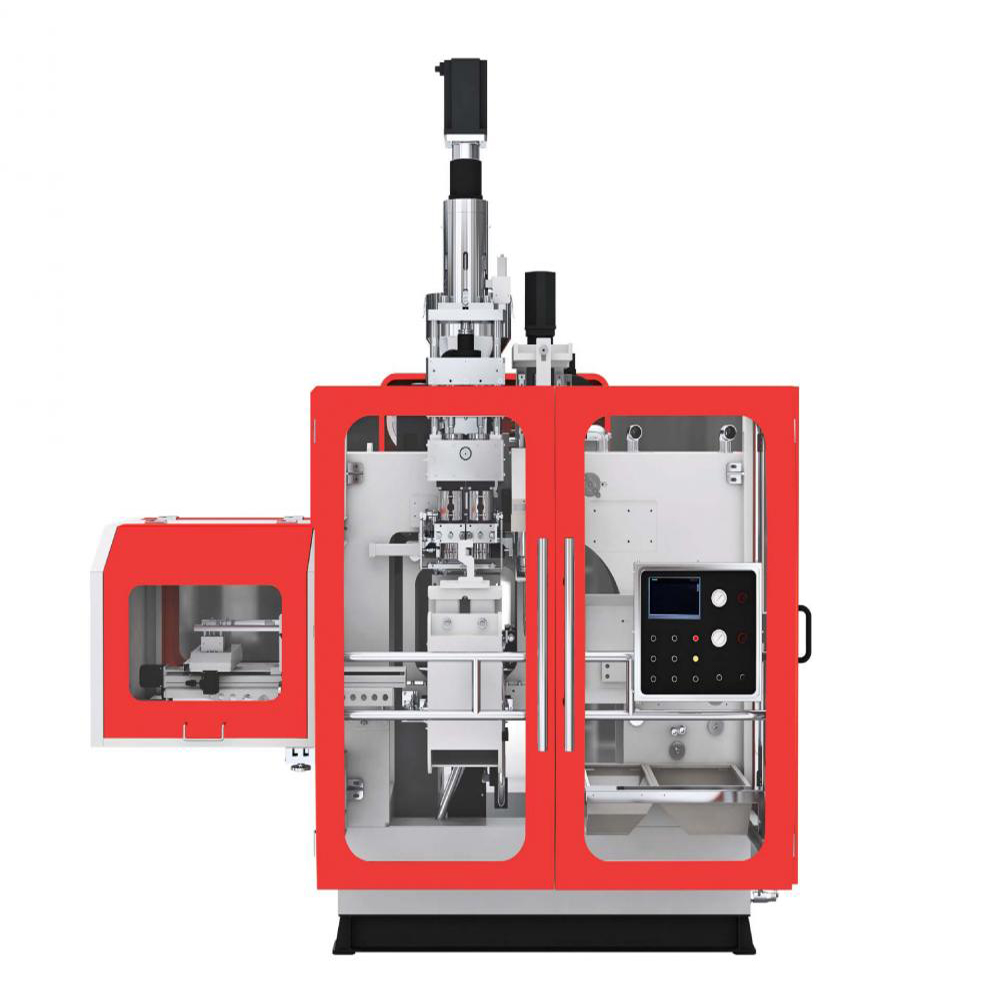

With consumer markets expanding and product variety increasing, the need for rapid, reliable, and cost-effective bottle production has never been greater. Sentis recognizes these challenges and has engineered its bottle blow molding machines to deliver high output production without compromising on quality or precision. These machines are designed to handle a wide range of bottle sizes and materials, making them adaptable for industries such as food and beverage, pharmaceuticals, cosmetics, and household chemicals.

The latest models from Sentis utilize cutting-edge automation and control systems that streamline the entire blow molding process. This not only boosts production rates but also minimizes downtime, ensuring manufacturers can keep up with fluctuating market demands.

Advanced Technology in Bottle Blow Molding Machines

Sentis’s bottle blow molding machines incorporate several technological advancements, including servo-driven systems, energy-efficient heating units, and intelligent monitoring software. These features allow for precise control over every stage of the molding process, from preform heating to bottle shaping and cooling.

- Servo-Driven Systems: Enhance accuracy and repeatability, ensuring consistent bottle quality across large production runs.

- Energy-Efficient Heating: Reduces operational costs and environmental impact, aligning with global sustainability goals.

- Intelligent Monitoring: Real-time data analytics enable proactive maintenance and rapid troubleshooting, minimizing production interruptions.

Such innovations have positioned Sentis as a trusted partner for companies seeking to optimize their manufacturing lines for both speed and reliability.

Industry Trends: Automation and Sustainability

The blow molding sector is experiencing a significant transformation driven by automation and sustainability. As labor costs rise and environmental regulations tighten, manufacturers are increasingly investing in machinery that can deliver high output production with minimal resource consumption.

Sentis’s commitment to these trends is evident in their latest bottle blow molding machines. Automation not only increases throughput but also reduces human error, leading to fewer defects and less material waste. Moreover, Sentis machines are designed to be compatible with recycled plastics and bioplastics, supporting circular economy initiatives and helping clients meet sustainability targets.

Global Impact and Customer Success Stories

Sentis Equipment Co.,Ltd has established a global footprint, supplying bottle blow molding machines to manufacturers in over 50 countries. Their equipment is renowned for its durability, ease of integration, and after-sales support. Clients report significant improvements in production capacity and product consistency after upgrading to Sentis solutions.

For example, a leading beverage producer in Southeast Asia recently partnered with Sentis to overhaul its bottling line. By installing Sentis’s high-output machines, the company increased its daily bottle production by 40% while reducing energy consumption by 15%. Similar success stories can be found across sectors, from pharmaceuticals to personal care.

The Role of PET Bottle Blow Molding and Injection Molding

Two essential keywords in the world of bottle manufacturing are PET bottle blow molding and injection molding. Sentis’s machines are fully compatible with PET (polyethylene terephthalate), the preferred material for lightweight, durable, and recyclable bottles. PET bottle blow molding ensures high clarity and strength, making it ideal for beverages and other liquids.

Additionally, Sentis integrates injection molding technology for preform production, ensuring seamless compatibility with their blow molding machines. This integration allows clients to manage the entire bottle production process from preform to finished product within a single, streamlined workflow.

Why Choose Sentis for High Output Bottle Production?

- Proven Track Record: Years of experience and a global client base.

- Innovative Technology: Always at the cutting edge of blow molding advancements.

- Comprehensive Support: From installation to maintenance and training.

- Customization: Machines tailored to specific production needs.

- Focus on Sustainability: Energy-saving designs and support for recycled materials.

Sentis continues to invest in research and development, ensuring their clients benefit from the latest advancements in bottle blow molding technology. Their machines are not only built for today’s demands but are also future-proofed to adapt to tomorrow’s challenges.

Conclusion: Shaping the Future of Bottle Manufacturing

As the packaging industry evolves, the need for efficient, high-output bottle production will only intensify. Sentis Equipment Co.,Ltd is committed to meeting this demand with state-of-the-art bottle blow molding machines that blend speed, quality, and sustainability. Through continuous innovation and customer-centric solutions, Sentis is helping manufacturers around the world achieve new heights of productivity and environmental responsibility.

For businesses seeking to stay ahead in a fast-paced market, partnering with Sentis means investing in technology that delivers results—today and for years to come.

Tags:Blow molding machine price,PE Blow molding machine supplier,PET Blow molding machine,Blow molding machine